- Description

- Reviews

- FAQs

Introduction

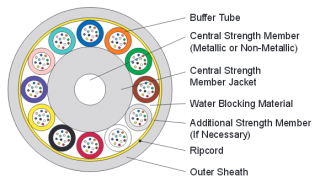

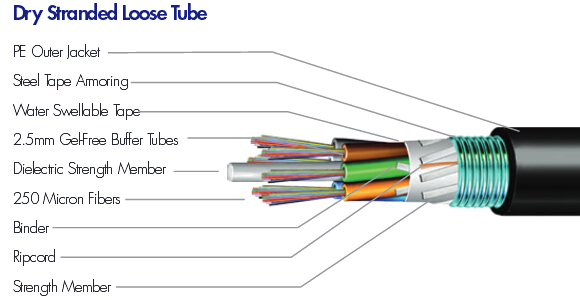

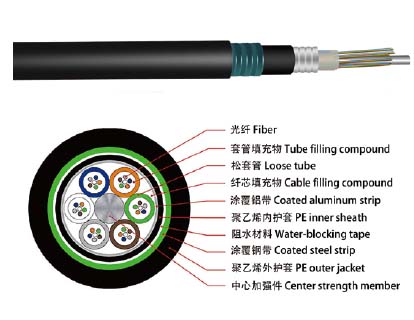

Loose tube fiber optic cables (hereinafter referred to as loose tube cables) are the most widely used cables for outside plant trunks because they offer the best protection for the fibers under high pulling tensions and can be easily protected from moisture with water-blocking gel or tapes. These cables are composed of several fibers together inside a small plastic tube, which are in turn wound around a central strength member, surrounded by aramid strength members and jacketed, providing a small, high fiber count cable (a basic structure of loose tube cable is shown below).

In loose tube cables, the coated fiber “floats” within a rugged, abrasion resistant, oversized tube which is generally filled with optical gel. Since the tube does not have direct contact with the fiber, any cable material expansion or contraction will not cause stress on the fiber. Much of the external stress placed on the tube also will not be transferred to the fiber. The non-hygroscopic gel prevents water from entering the tube. The loose tube cables are proven the best solution for harsh environment conditions in the outdoors. For example, they can be used in conduits, strung overhead or buried directly into the ground. Some outdoor loose tube cables may have double jackets with a metallic armor between them to protect from chewing by rodents or kevlar for strength to allow pulling by the jackets. Since the fibers have only a thin buffer coating, they must be carefully handled and protected to prevent damage.Different Types of Loose Tube Cables

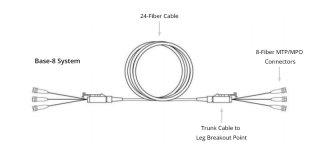

According to different attributes, there are different types of loose tube cables. Similar to the other fiber optic cables, there are single mode loose tube cables and multimode loose tube cables classified by the fiber types. Loose tube cables with single mode fibers are generally terminated by spicing pigtails onto the fibers and protecting them in a splice closure. However, multimode loose tube cables can be terminated directly by installing a breakout kit (also called a furcation or fan-out kit) which sleeves each fiber for protection.

READ MORE ...Fiber Splicing and Termination TipsActually on the market, the loose tube cables are more commonly classified by different structures. The “structure” includes fiber counts, materials of the jacket and even more. The different types are shown as following.Central Loose Tube Cables

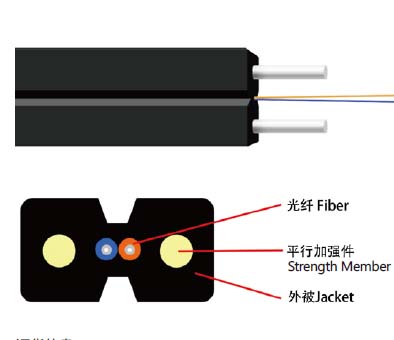

Central loose tube cables have up to 24 fibers in a robust all dielectric design. The central loose tube design is the economical option for low fiber counts not more than 24 fibers. It offers a smaller overall dimension and ensures a more efficient use of conduit space than typical loose tube. The central tube minimizes the amount of labor and material required to install the cable. The number of breakout kits can be reduced by 50%, saving time, money and space.

Central Loose Tube Cable with LSZH Jacket![]()

Central Loose Tube Cable with PE JacketMulti Loose Tube Cables

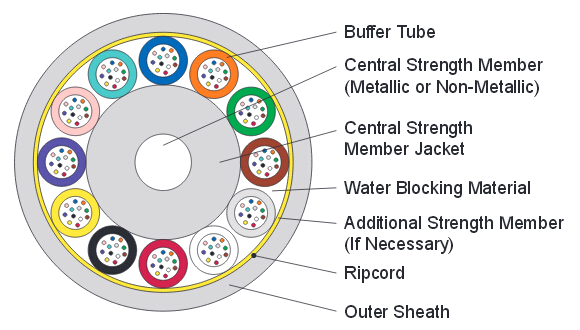

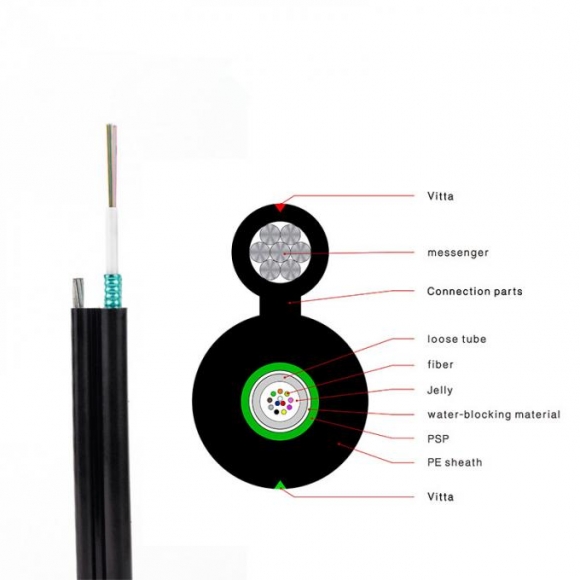

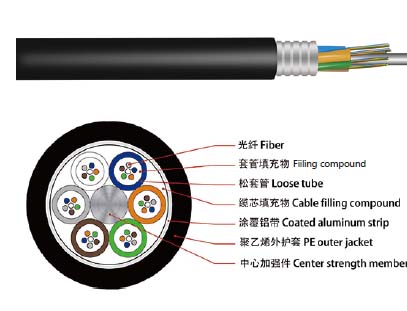

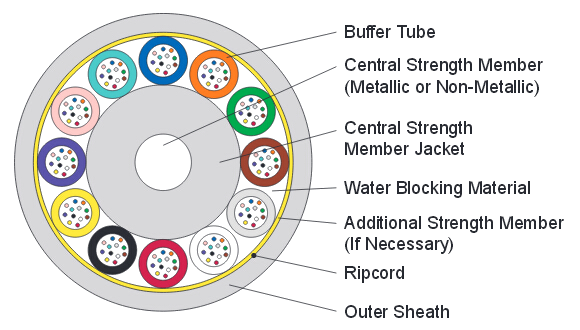

Multi loose tube cable is designed with a multi-tube structure for higher fiber count needs. The multi-tube structure is made of an assembly of different tubes around a central strength element. The fiber count ranges widely dependent on location of active equipment. For outdoor installation, multi loose tube cable is designed with resistant outer sheath, generally made of polyethylene to resist to more severe environment constraints (abrasion, temperature variation, crush resistance etc.). It features a watertight conception, obtained by using jelly and/or swellable elements, to stop the water propagation within the cable in case of cable accident. Such outdoor loose tube cables are mainly installed in ducts or directly buried. Tips: In some case, Indoor-Outdoor structures are required to combine the water tightness characteristics and LSZH-FR sheath in the multi loose tube cables.

Multi Loose Tube Cable with LSZH Jacket

Multi Loose Tube Cable with PE JacketStranded Loose Tube Cables

Stranded loose tube cable is a non-metallic cable used in power transmission systems in places where there are high electromagnetic interferences and long distance telecommunications. Extremely flexible and economical, this cable is ideal for low fiber count applications such as in aerial, duct, direct burial installations and riser indoor spaces. The cable construction consists of an FRP (Fiber Reinforced Plastic) that is located in the center of the cores as a non-metallic strength member. The cable tubes which are filled with filling compounds, are stranded around the strength members and the aramid yarn is applied over water proof material. The cable is completed with a fire retardant PE sheath.

| A New-Type Stranded Loose Tube Cable—Dry Loose Tube CableDry loose tube cable is a kind of gel-free stranded loose tube cable. It uses all-dry water blocking technology and reduced diameter buffer tubes. The dry loose tube cable design is completely gel-free, yet it provides full water blocking protection for outside plant applications. The dry loose tube cables are an alternative to standard gel-filled loose tube cables. | Benefits of Dry Loose Tube Cable:Decreases cable prep timeEliminates need for potentially hazardous solventsLess consumable materials requiredCleaner, improved work environmentImproves lifespan of equipmentSimplifies work site clean-upImproves ease of handlingEasier routing inside the enclosureMaximizes tube spaceImproves reel capacity |

Summary

Loose tube cable has been the dominant fiber optic cable design deployed in campus backbones for more than 25 years. In recent years, this design has also emerged as a major choice for building backbones where riser and plenum flame ratings are required. The loose tube cable has demonstrated exceptional and reliable mechanical, environmental, and optical performance that has been unmatched by any other optical cable designs and other media types.

- Customers Reviews

* Delivery Time.

We need 1-2 days to process your order before shipping. There are two shipping methoed.

Fast Delivery: The delivery time for US, European countries the delivery will take 3-5 days.

Slow Delivery: The delivery time for US, European countries the delivery will take 7-15 days.

* Tracking information.

After we ship package, customer receive automatic email with tracking details.

* Lost Package Policy.

If a package did not arrive in 2 weeks after the shipping date, then this package is treated as Lost. In this case a new package will be shipped to the customer provided we are able to give the same items as those purchased by the customer. If we are not able to provide the same items to substitute the lost ones we will either propose to the customer similar items or refund their cost as it will be mutually agree with the customer. If one or more items neither the same nor similar are available to be shipped, the customer can request to cancel the order entirely, thus the total cost of the order including shipping and handling cost will be fully refunded.

(0)

(0) (0)

(0) (0)

(0) (0)

(0) (0)

(0)